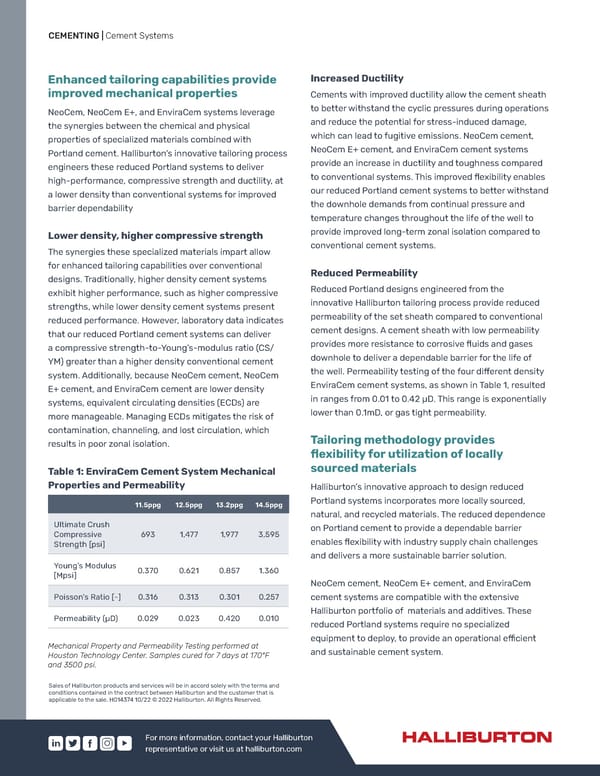

Enhanced tailoring capabilities provide improved mechanical properties NeoCem, NeoCem E+, and EnviraCem systems leverage the synergies between the chemical and physical properties of specialized materials combined with Portland cement. Halliburton’s innovative tailoring process engineers these reduced Portland systems to deliver high-performance, compressive strength and ductility, at a lower density than conventional systems for improved barrier dependability Lower density, higher compressive strength The synergies these specialized materials impart allow for enhanced tailoring capabilities over conventional designs. Traditionally, higher density cement systems exhibit higher performance, such as higher compressive strengths, while lower density cement systems present reduced performance. However, laboratory data indicates that our reduced Portland cement systems can deliver a compressive strength-to-Young’s-modulus ratio (CS/ YM) greater than a higher density conventional cement system. Additionally, because NeoCem cement, NeoCem E+ cement, and EnviraCem cement are lower density systems, equivalent circulating densities (ECDs) are more manageable. Managing ECDs mitigates the risk of contamination, channeling, and lost circulation, which results in poor zonal isolation. Table 1: EnviraCem Cement System Mechanical Properties and Permeability 11.5ppg 12.5ppg 13.2ppg 14.5ppg Ultimate Crush Compressive Strength [psi] 693 1,477 1,977 3,595 Young’s Modulus [Mpsi] 0.370 0.621 0.857 1.360 Poisson’s Ratio [-] 0.316 0.313 0.301 0.257 Permeability (μD) 0.029 0.023 0.420 0.010 Increased Ductility Cements with improved ductility allow the cement sheath to better withstand the cyclic pressures during operations and reduce the potential for stress-induced damage, which can lead to fugitive emissions. NeoCem cement, NeoCem E+ cement, and EnviraCem cement systems provide an increase in ductility and toughness compared to conventional systems. This improved flexibility enables our reduced Portland cement systems to better withstand the downhole demands from continual pressure and temperature changes throughout the life of the well to provide improved long-term zonal isolation compared to conventional cement systems. Reduced Permeability Reduced Portland designs engineered from the innovative Halliburton tailoring process provide reduced permeability of the set sheath compared to conventional cement designs. A cement sheath with low permeability provides more resistance to corrosive fluids and gases downhole to deliver a dependable barrier for the life of the well. Permeability testing of the four different density EnviraCem cement systems, as shown in Table 1, resulted in ranges from 0.01 to 0.42 μD. This range is exponentially lower than 0.1mD, or gas tight permeability. Tailoring methodology provides flexibility for utilization of locally sourced materials Halliburton’s innovative approach to design reduced Portland systems incorporates more locally sourced, natural, and recycled materials. The reduced dependence on Portland cement to provide a dependable barrier enables flexibility with industry supply chain challenges and delivers a more sustainable barrier solution. NeoCem cement, NeoCem E+ cement, and EnviraCem cement systems are compatible with the extensive Halliburton portfolio of materials and additives. These reduced Portland systems require no specialized equipment to deploy, to provide an operational efficient and sustainable cement system. CEMENTING | Cement Systems Mechanical Property and Permeability Testing performed at Houston Technology Center. Samples cured for 7 days at 170°F and 3500 psi. Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the contract between Halliburton and the customer that is applicable to the sale. H014374 10/22 © 2022 Halliburton. All Rights Reserved. For more information, contact your Halliburton representative or visit us at halliburton.com

Reduced Portland Cement Systems - Data Sheet Page 1

Reduced Portland Cement Systems - Data Sheet Page 1